A back plate, also known as a backing plate, serves as a crucial component in various mechanical and industrial applications. It is a flat, sturdy piece typically made from materials like steel, aluminum, or composite materials, designed to provide structural support and reinforcement to a wide range of systems and equipment.

In the automotive industry, back plates are commonly used as a vital component in braking systems. They are positioned behind the brake pads, forming a secure platform that ensures uniform pressure distribution and thermal stability during braking. This crucial role not only enhances braking performance but also contributes to the safety of vehicles on the road.

In industrial machinery, back plates find application in diverse scenarios, from belt-driven systems to heavy machinery and conveyors. These plates offer stability and support, preventing vibration and misalignment, thereby extending the operational lifespan of the equipment and minimizing downtime.

Back plates are not limited to a specific industry; they are versatile components used in countless applications, ranging from mounting brackets in electronics to structural reinforcements in construction projects. Their design and material composition can be customized to meet specific needs, making them indispensable in engineering solutions that demand strength, durability, and reliability.

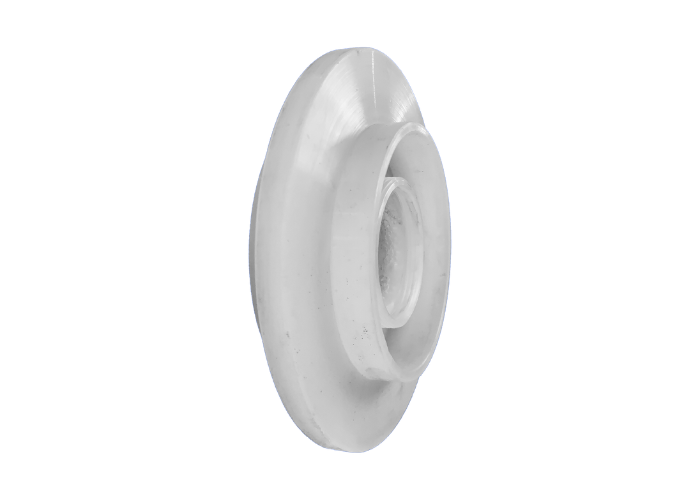

Mechanical seal

Paraflon pumps are whole FEP/PFA pump body, cantilever structure, no load bearing, but light and easy to maintain.

Actual use showed that the pump has the advantages of corrosion resistance, wear resistance, high temperature resistant, not aging, high mechanical strength, stable operation, advanced structure, reliable sealed performance, simple disassembly and maintenance, low noise, long service life etc.

Paraflon pumps are in accordance with international standards and non-metallic pump technology combined with design and manufacturing.

The pump can be used in transporting strong corrosive medium of any concentration, such as sulfuric acid, hydrochloric acid, nitric acid, acetic acid, aqua regia, strong alkali, strong oxidants and organic solvents, etc. It is one of the most advanced corrosion-resistant equipment.

1.Chlor-Alkali Electrolysis

2.Sulphuric acid

3.Steel and Stainless steel pickles

4.Titanium dioxide

5.Phosphoric acid

6.Sea water

7.Waste incineration (flue gas cleaning)

8.Scrubber

9.Waste water

10.Hydrochlorid acid

| Specification | Description |

|---|---|

| Material | Steel, Aluminum, Composite, etc. |

| Size | Customizable to application requirements |

| Thickness | Varies based on application, typically 1-10 mm |

| Shape | Typically flat and rectangular |

| Surface Finish | Smooth, often with a protective coating |

| Mounting Holes | Number and configuration vary |

| Weight | Depending on size and material |

| Application | Brake systems, machinery support, construction, etc. |

| Customization | Can be tailored to specific application needs |

| Strength and Durability | High strength, excellent durability |

| Vibration and Alignment | Provides stability, reduces vibration and misalignment |

| Corrosion Resistance | May require corrosion-resistant coatings |

| Heat Resistance | Can be designed for high-temperature applications |

| Compliance Standards | Depending on industry and application |

Choosing Teflon valves for your applications offers several compelling reasons

Back plates are typically constructed from materials known for their strength and durability. This durability ensures they can withstand the rigors of industrial applications.

Back plates find applications in various industries, from automotive to construction, electronics, and more. Their versatility makes them an essential component.

Back plates help reduce vibration and minimize misalignment, which is essential for machinery and equipment where precise alignment is critical to operational efficiency.