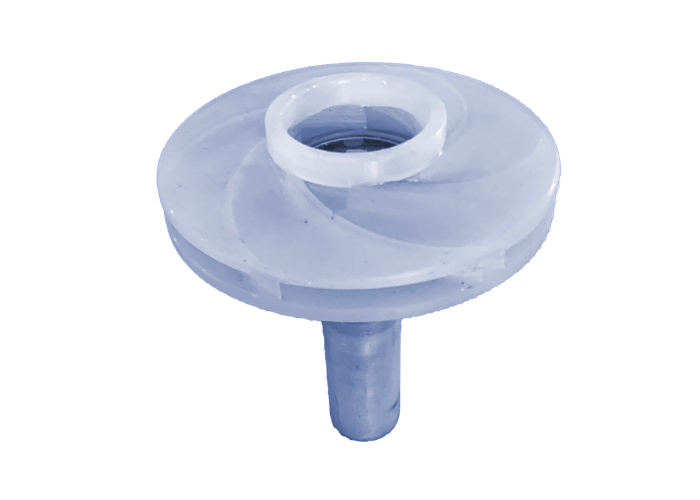

– Impeller with METAL INSERTS MOLDED WITH FEP/PFA/PVDF

– T impeller

– High temperature resistance,

– safety and reliability

– Resistant to corrosion

– Not easily deformed

– high mechanical strength

An impeller, whether closed or semi-open, is a vital component in various mechanical systems, particularly within the realm of fluid dynamics. It plays a pivotal role in facilitating the movement and control of fluids, making it an indispensable part of pumps, mixers, and agitators across diverse industries.

A closed impeller is characterized by its solid, disk-like design with blades that are fully shrouded, enclosing the fluid completely within the impeller. This configuration ensures efficient fluid movement, minimal leakage, and high-pressure capabilities. Closed impellers are often preferred in applications where the fluid being transported is abrasive, viscous, or contains solid particles. They excel in environments that demand high head and are known for their superior performance in industrial processes, including water treatment, chemical manufacturing, and wastewater management.

On the other hand, a semi-open impeller is recognized by its partially exposed blades, allowing for greater flexibility in handling fluids with larger solids, high viscosity, or those prone to clogging. This design minimizes the risk of clogs and simplifies maintenance, making semi-open impellers well-suited for applications such as slurry pumping, municipal sewage systems, and agriculture.

Both closed and semi-open impellers are meticulously engineered to meet specific operational requirements and are available in a variety of materials, including stainless steel, cast iron, and various polymers, to ensure compatibility with a wide range of fluids and environmental conditions.

Choosing Teflon valves for your applications offers several compelling reasons

Their high efficiency and excellent hydraulic performance. They are ideal for applications where maximizing head and flow rate is crucial.

Impellers are well-suited for handling abrasive or aggressive fluids, making them a preferred choice in industries where corrosion and wear are concerns.

Impellers are available in a wide range of materials, allowing you to select the one most compatible with your specific fluid.