Teflon valves have emerged as indispensable components in various industrial applications, offering unique advantages that make them stand out in the realm of fluid control systems. Teflon, a brand name for polytetrafluoroethylene (PTFE), possesses remarkable properties, such as high chemical resistance, non-stick surfaces, and excellent thermal stability. These qualities make Teflon valves ideal for demanding industrial processes where precision, durability, and reliability are paramount.

Chemical Resistance: Teflon valves excel in applications where they come into contact with corrosive chemicals or aggressive substances. The inherent resistance of Teflon to a wide range of chemicals ensures that the valves maintain their structural integrity and functionality even in harsh environments.

Non-Stick Properties: The non-stick nature of Teflon significantly reduces the risk of valve clogging or build-up of residues, enhancing the efficiency of fluid flow. This property is particularly valuable in applications where cleanliness and fluid purity are critical, such as in pharmaceutical and food processing industries.

Temperature Stability: Teflon valves can withstand a broad temperature range without losing their mechanical properties. This makes them suitable for processes involving extreme temperatures, whether it’s handling hot substances in chemical manufacturing or managing cryogenic fluids.

Low Friction Coefficient: The low friction coefficient of Teflon contributes to smooth and precise valve operation. This feature is essential in applications requiring accurate flow control and where the prevention of leaks or drips is crucial.

| Specification | Description |

|---|---|

| Material | Polytetrafluoroethylene (PTFE) – Teflon |

| Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| Pressure Range | Varies based on valve type and size |

| Chemical Compatibility | Excellent resistance to a wide range of chemicals |

| Non-Stick Properties | Yes – Reduces the risk of clogging and residue build-up |

| Friction Coefficient | Low – Enables smooth and precise valve operation |

| Applications | Chemical processing, pharmaceuticals, food and beverage, water treatment, etc. |

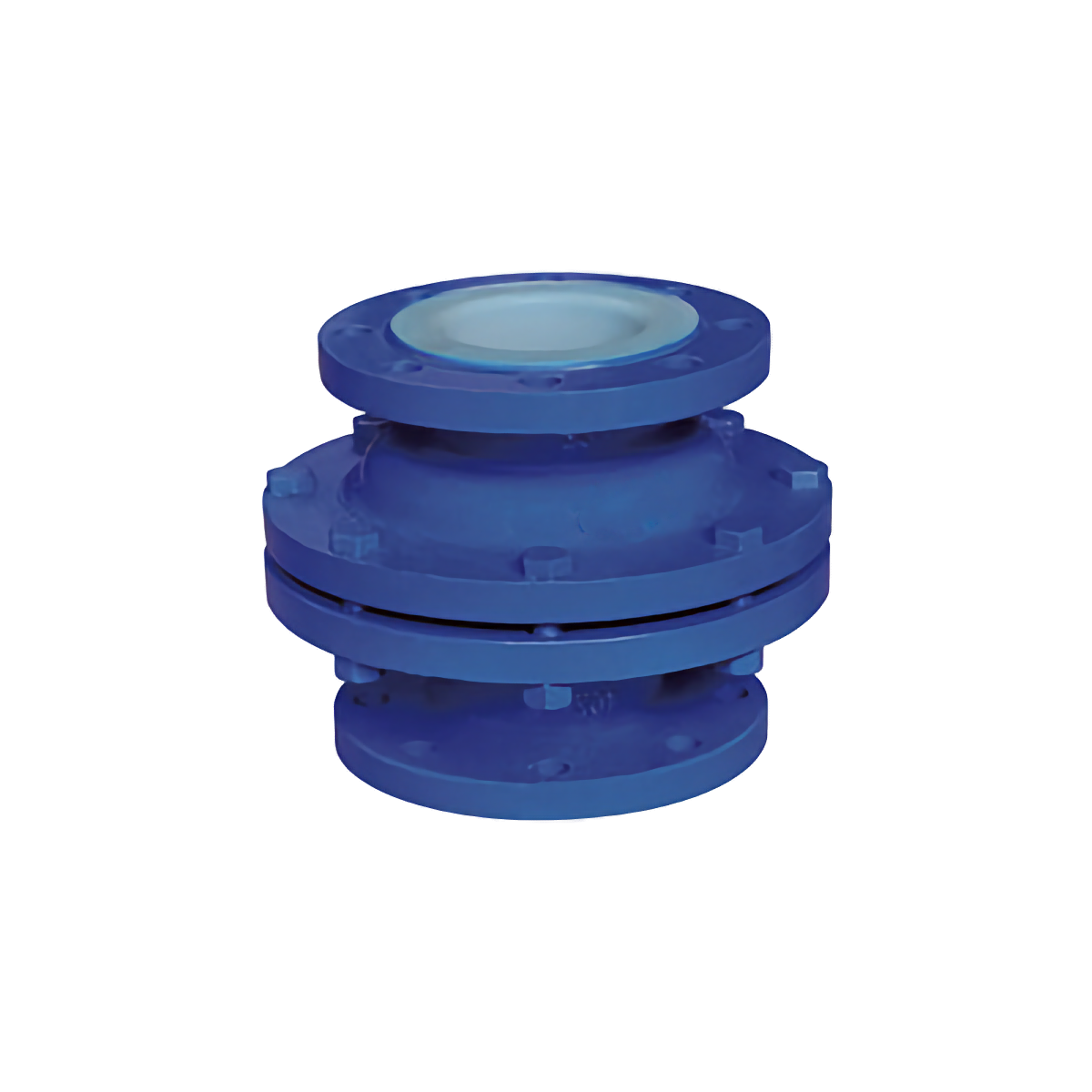

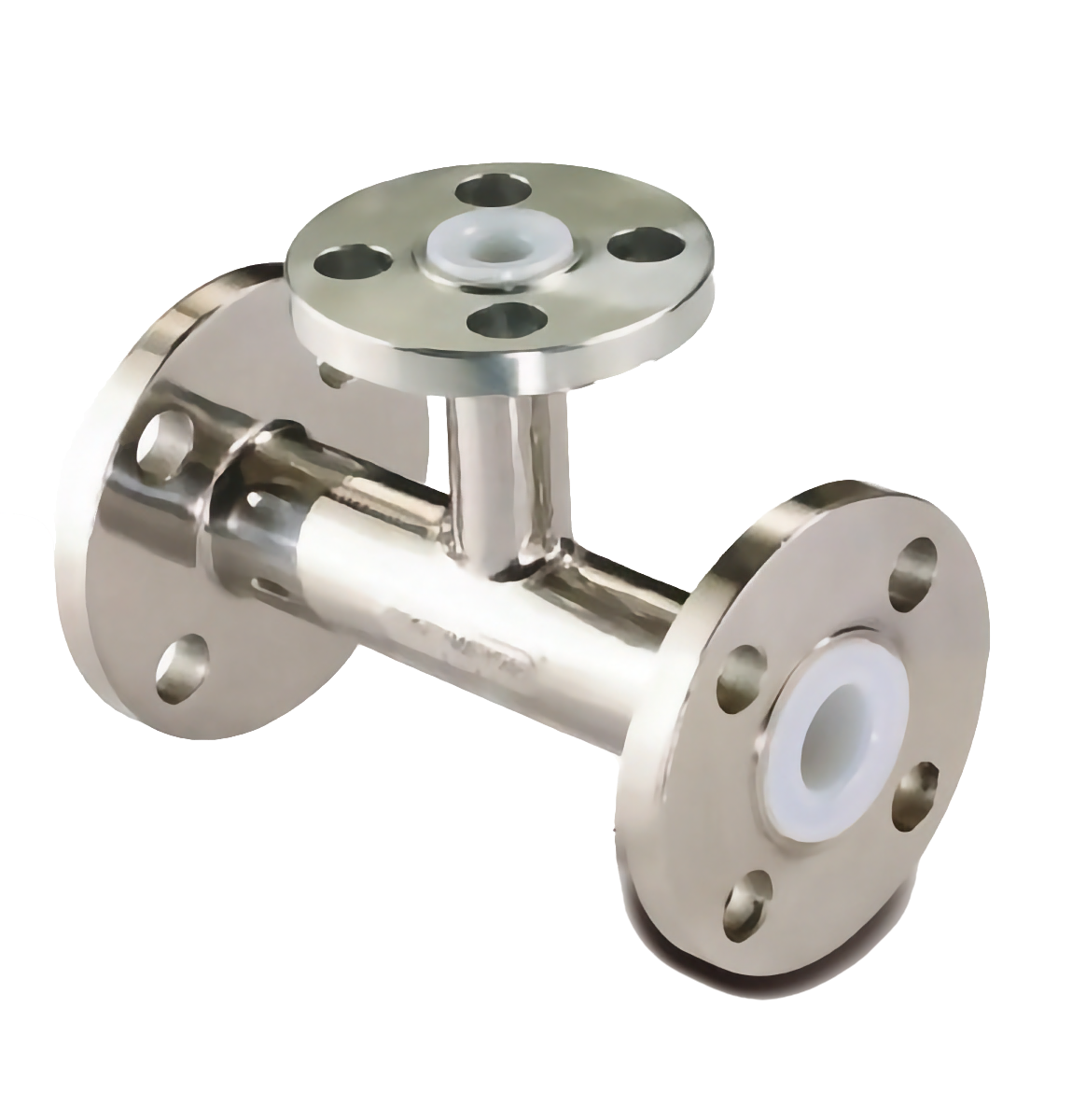

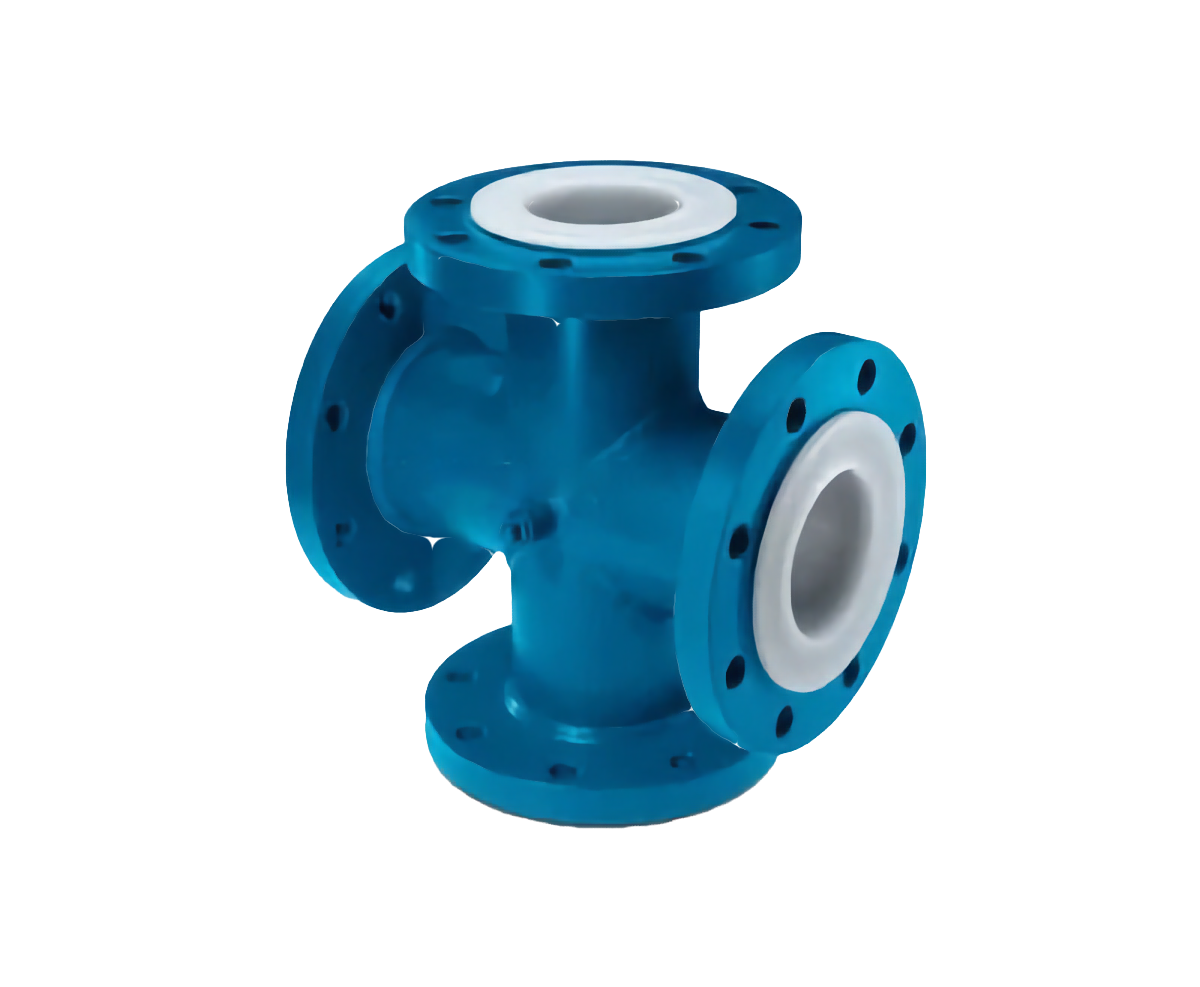

| Valve Types | Ball valves, butterfly valves, diaphragm valves, etc. |

| Size Range | Varied sizes available, ranging from small to large |

| End Connection Types | Threaded, flanged, butt-weld, etc. |

| Industry Standards | Compliance with relevant industry standards and certifications |

| Maintenance | Minimal maintenance required due to Teflon’s durability and non-stick properties |

| Environmental Impact | Generally considered environmentally friendly due to PTFE’s inert nature |

| Cost Consideration | Initial cost may be higher, but cost-effective in the long run due to durability |

Choosing Teflon valves for your applications offers several compelling reasons

These valves maintain their structural integrity at elevated temperatures, ensuring reliable performance.

Teflon valves are built to last, requiring minimal maintenance, reducing downtime, and lowering operational costs.

Teflon valves find applications in chemical processing, petrochemicals, pharmaceuticals, food and beverage, and many other industries.