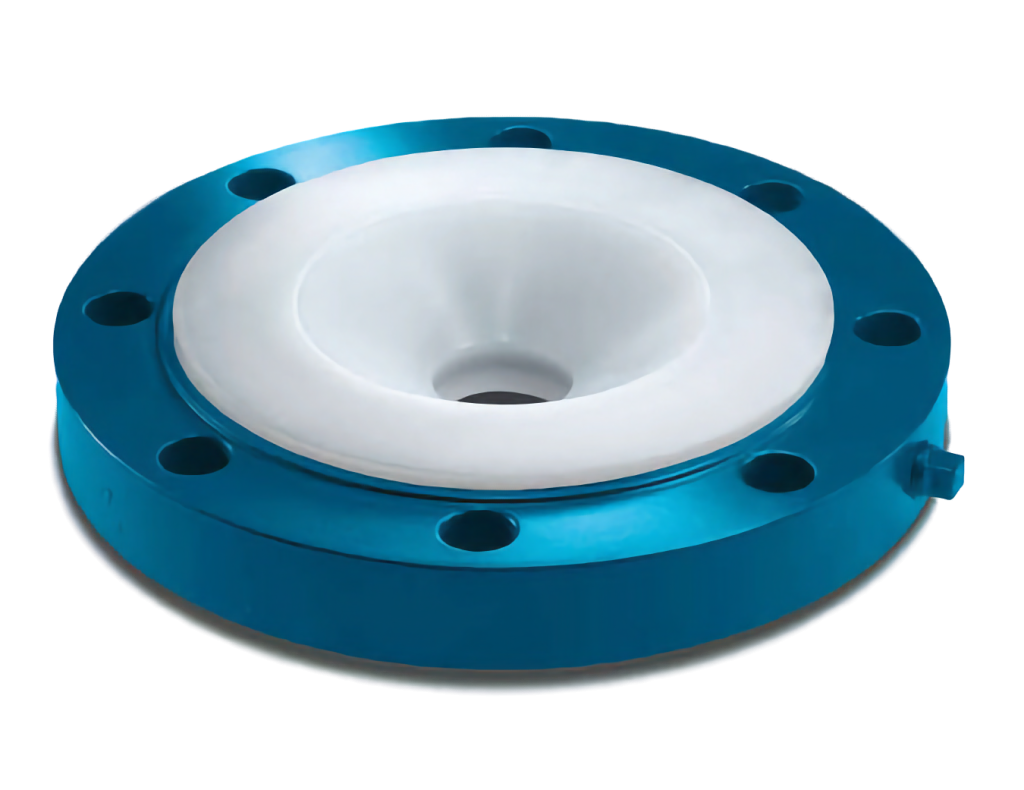

PTFE Lined Flanges: Unparalleled Corrosion Resistance and Sealing Solutions

In the world of fluid handling systems, PTFE lined flanges are the unsung heroes. These remarkable components provide an essential link between pipelines, ensuring not only the seamless flow of corrosive and high-purity fluids but also the safeguarding of your equipment and processes.

1. Superior Corrosion Resistance: PTFE (Polytetrafluoroethylene) is renowned for its exceptional resistance to a wide range of corrosive chemicals and aggressive substances. PTFE lined flanges act as a protective barrier, shielding your pipelines and equipment from the damaging effects of acids, bases, solvents, and more. This resistance extends to elevated temperatures, making them suitable for various industries, including chemical processing, pharmaceuticals, and petrochemicals.

2. Secure Leak-Free Connections: One of the primary functions of PTFE lined flanges is to create a secure, leak-free connection between pipes, valves, and other equipment. The PTFE lining not only resists chemical attack but also provides an excellent sealing surface. This ensures that your fluid handling system operates efficiently and safely, minimizing the risk of leaks or contamination.

3. Versatility and Adaptability: PTFE lined flanges are versatile and adaptable, available in various sizes and specifications to fit the unique requirements of your application. Whether you need them in standard dimensions or custom-made to suit specific needs, they offer flexibility and compatibility with a wide range of process systems.

4. Durability and Longevity: These flanges are built to last. PTFE lining is not only corrosion-resistant but also highly durable, providing a long service life and reducing the need for frequent replacements and maintenance. This longevity translates into cost savings and enhanced operational reliability.

5. Compliance and Safety: PTFE lined flanges adhere to strict industry standards and regulations, ensuring compliance with safety and environmental requirements. They are an ideal choice for industries where the handling of hazardous or sensitive materials is a concern.

| Specification | Description |

|---|---|

| Material | PTFE (Polytetrafluoroethylene) lining with various flange material options (e.g., carbon steel, stainless steel) |

| Flange Size | Available in standard sizes from 1/2″ to 24″ and custom sizes upon request |

| Pressure Rating | ANSI Class 150, 300, 600, 900, or customized for specific applications |

| Temperature Range | -20°C to 200°C (-4°F to 392°F) depending on lining and flange material |

| Corrosion Resistance | Excellent resistance to a wide range of corrosive chemicals and high-purity fluids |

| Sealing Performance | Provides a secure and leak-free connection between components |

| Flange Standards | Compliant with ANSI, DIN, or custom flange standards as required |

| Customization | Available for unique applications, including different flange materials and sizes |

| Durability | Long service life, reducing maintenance and replacement costs |

| Compliance | Conforms to industry safety and environmental regulations |