Unrivaled Corrosion Resistance: PTFE lining is impervious to a broad spectrum of corrosive substances, including strong acids, bases, and solvents. This exceptional resistance ensures the integrity of the piping system over time, reducing maintenance costs and increasing operational safety.

Smooth, Low-Friction Surface: The inherent non-stick properties of PTFE create a smooth internal surface, promoting efficient fluid flow and minimizing the risk of blockages or buildup within the pipes. This contributes to the overall efficiency of your processes.

High Temperature Tolerance: PTFE lined pipes can withstand a wide temperature range, from cryogenic conditions to high-temperature applications. This versatility makes them suitable for use in diverse industries such as chemical processing, pharmaceuticals, and petrochemicals.

Exceptional Chemical Compatibility: PTFE’s broad chemical resistance allows these pipes to handle a vast array of aggressive media, ensuring the safe and reliable transport of critical substances without the risk of contamination or degradation.

Longevity and Low Maintenance: PTFE lined pipes have a prolonged service life, reducing the need for frequent replacements. This results in lower maintenance costs and increased production uptime.

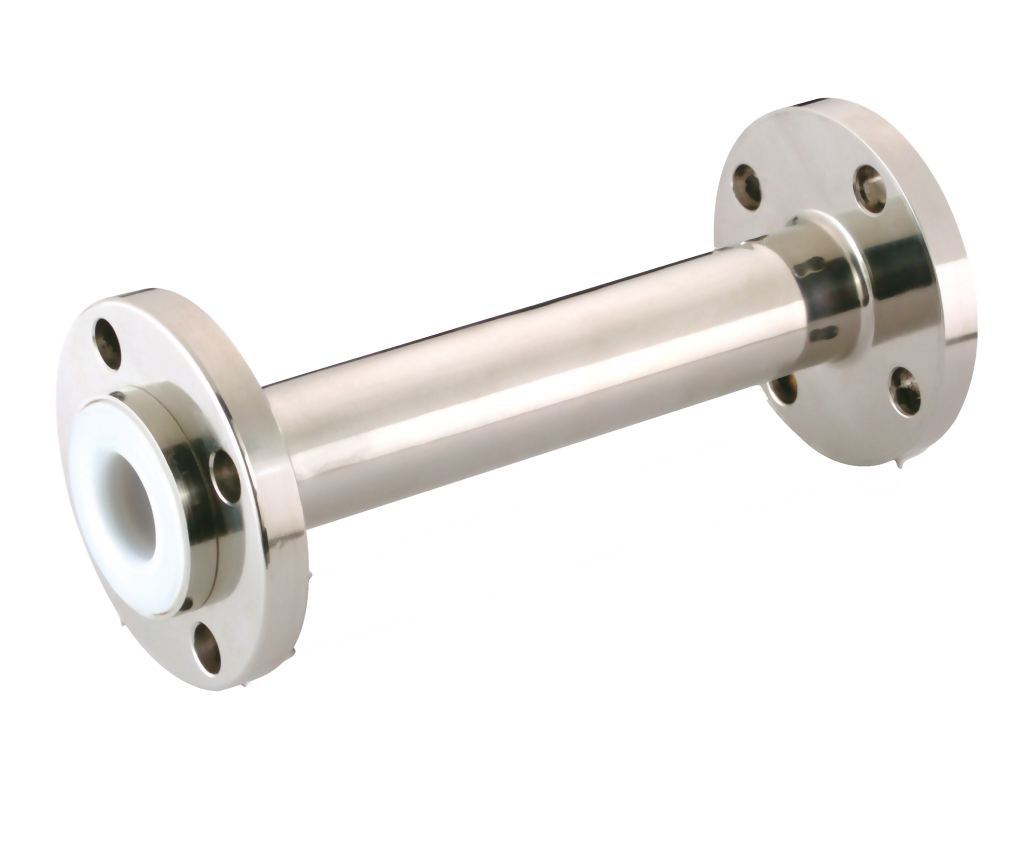

Customization: These pipes can be customized to meet the specific requirements of your application, including various sizes, connection types, and lining thicknesses.

PTFE lined pipes find application in various industries, including:

| Specification | Description |

|---|---|

| Material | PTFE (Polytetrafluoroethylene) lining |

| Base Pipe Material | Varies (typically carbon steel, stainless steel) |

| Corrosion Resistance | Excellent resistance to corrosive chemicals |

| Temperature Range | -50°C to 260°C (-58°F to 500°F) |

| Smoothness | Ultra-smooth interior surface for low friction |

| Chemical Compatibility | Broad spectrum, suitable for aggressive media |

| Customization | Available in various sizes and connection types |

| Thickness of Lining | Customizable for specific application requirements |

| Applications | Chemical processing, pharmaceuticals, petrochemicals, food and beverage, water treatment, electronics, and more |

| Longevity | Extended service life, reducing maintenance costs |

| Maintenance | Low maintenance requirements |